PE/PP/ABS/PC/PVC/PS/PBT Nitridged Steel Mini Twin Screw Extruder

Lab Plastic Pelletizing Machine

Yongjie laboratory mini extruder SJSL20 is widely used among our

customers of universities, research center, and factory R&D

department for the testing of formula, compounding etc.

There are two electric control type, PID centralized contrial and

SIEMENS PLC touch screen control.

Quick details

Power:5.5kw

Screw diameter:21.7mm

Screw material:38CrMoAL

Barrel diameter:22mm

Barrel material:38CrMoAL

Output:around2-15kg/h

Dryer:0.26kw

Pelletizer:0.75kw

Cutting way: water strand, air cooling strand also available

Warranty:one year

Lead time:45 days after deposit

Heating power:16kw

Heating zones: 7zones

Barrel length:120*7=840mm

Control type:PID or PLC

Screw

Diameter:¢21.7mm

L/D:40:1

Direction of rotation: Co-rotating

Screw & elements: W6Mo5Cr4V2 (6542#) high speed tool steel that had been treated by the vacuum

hardening process with the hardness of the surface is HRC58-62.Molding through dedicated grinding machine. The cleanliness is

much better than products out of traditional process.

Core axle: High quality alloy steel 40CrNiMo that with high tenacity and durability. It had been treated by the

hardening and tempering process.

Barrel

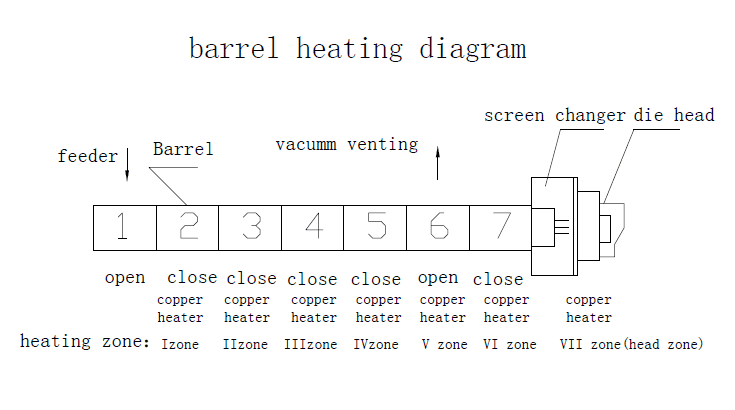

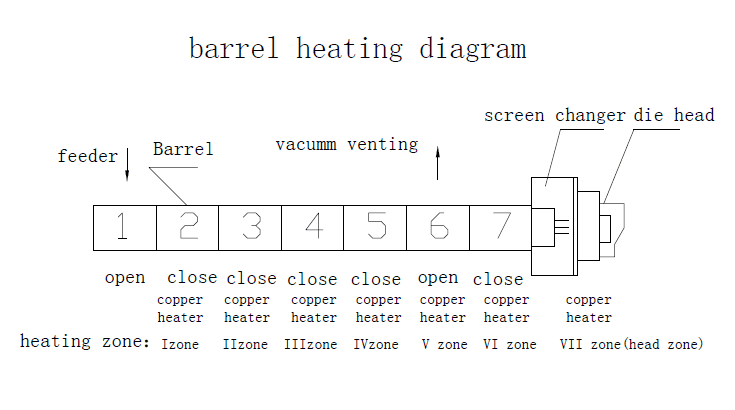

1). Structure: The first section works for main feeding, and the sixth section is set up for vacuum venting, the others are blocked.

2). Material: The material of the barrel 38CrMoAlA, surface hardness: HV950-1050, depth 0.5-0.7mm 3). Heating: Adopt multiple step format electric heating. All zones are cast

copper heater. The total heating power is 16KW and the max heating capacity every section can reach

500℃.

4). Cooling: Adopt soft water cooling system in the barrel and tap water

cooling way outside barrel. The circulation pipes are made of

stainless steel and the water inflow regulating valves are

stainless valves.

The brand of electromagnetic valve is DANFOSS.

5). Length: 120*7=840mm

World famous brands of electronic components

1). Temperature control meter is Japanese RKC meter, intelligent type, double channel;

2). The inverter of extruder is ABB;

3). The low-voltage apparatus and the button adopt SCHNEIDER product;

4). AC contactor adopt SIEMENS product;

5). The main motor is SISMENS BEIDE;

6). The air switch adopts CHINT products. The solid-state relays are from American joint venture

brand;

7). The electromagnetic valve: adopt Denmark DANFOSS product.

Scope of supply

| No. | Contents | Unit | Quantity | Marks |

| 1 | Twin screw extrusion system | set | 1 | |

| 1.1 | Feeding system | set | 1 | 0.25kw |

| 1.2 | SJ-20 Twin screw extruder | set | 1 | 5.5kw, 40:1 |

| 1.3 | Vacuum venting system | set | 1 | 0.75kw |

| 1.4 | Water cycling system | set | 1 | 0.55kw |

| 1.5 | Manual screen changer | set | 1 | |

| 2 | Electric cabinet | set | 1 | |

| 3 | Water stand auxiliary system | set | 1 | |

| 3.1 | Die head | set | 1 | |

| 3.2 | Water trough | set | 1 | 1 M |

| 3.3 | Dryer | set | 1 | 0.26KW |

| 3.4 | Pelletizer | set | 1 | 0.75KW |

| 4 | Documents | set | 1 | |

Photo of Laboratory Mini Extruder

Main technical data of various model of twin screw extruder

pelleitizing machine

| Model type | Series | Barrel Diameter (mm) | Screw Diameter (mm) | Screw L/D | screw speed n(r/min) | Main motor power(Kw) | Screw torque T(N.m) | Torque rating (T/A3) | Typical production capacity (kg/h) |

| SJSL20 | A/B | 22 | 21.7 | 32-44 | 500/600 | 4/5.5kw | 30/30 | | |

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Company Brief

Nanjing Yongjie Qixin Machinery Equipment Co.,Ltd Founded in 2001, covers an area of 20,000 square meters on our own

land, with monthly output of machine 20sets. Our factory is

certificated to CE, ISO9001:2008.The company concentrates on

research, development and production of “high level, accurate,

highly sophisticated series product parallel co-rotating “cordwood”

twin screw extruder, single screw extruder, two stage extruders and

automatic plastic pelletizing machines. We have provided customers

first-class products with “strong torque, high production, energy

conservation and environmental protection products. The special